特点:

轴套采用不锈钢制成,耐酸、碱

大扭矩、体积小巧、零回转间隙

胶体采用德国TPU,经特殊工艺加工制造,24小时压缩变型率仅为15%,优于普通材料35%

采用95A适中胶体硬度,解决偏软影响精度,超硬缓冲不足的问题

耐高低温、温度适用范围:-30到+100℃

中间弹性体可吸收振动、补偿径向、角向和轴向偏差

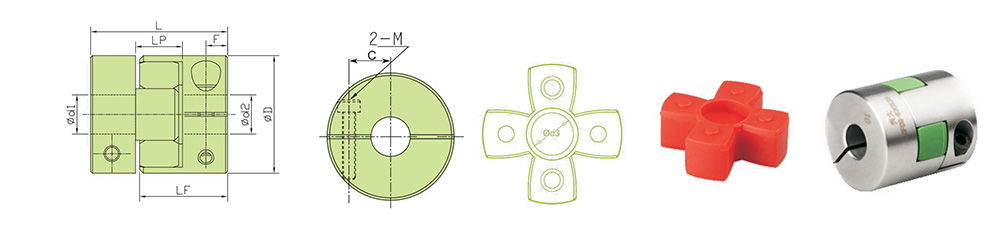

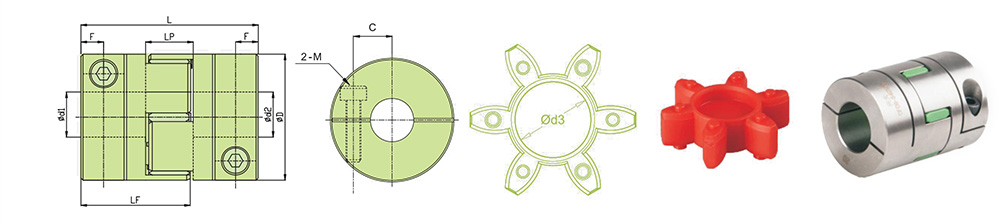

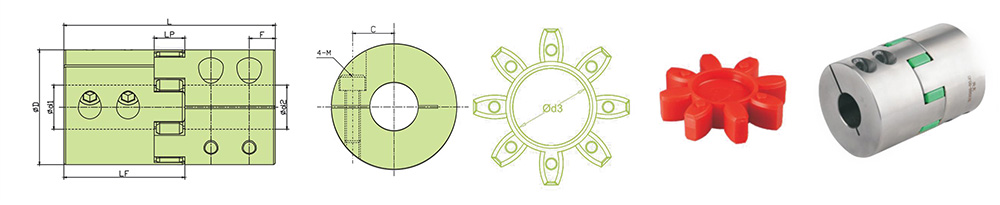

外型尺寸 (单位): mm

|

型号 |

ØD |

L |

LF |

LP |

F |

C |

Φd3 |

M |

紧固扭矩(N·M) |

|

CFCG-S20×25 |

Ø20 |

25 |

16.8 |

9.4 |

4 |

5.9 |

7.8 |

2-M3×10 |

3 |

|

CFCG-S20×30 |

Ø20 |

30 |

19.3 |

9.4 |

5.25 |

5.9 |

7.8 |

2-M3×10 |

3 |

|

CFCG-S25×30 |

Ø25 |

30 |

20.15 |

11.1 |

4.6 |

7.3 |

8.3 |

2-M4×12 |

7 |

|

CFCG-S25×34 |

Ø25 |

34 |

22.15 |

11.1 |

5.55 |

7.3 |

8.3 |

2-M4×12 |

7 |

|

CFCG-S30×35 |

Ø30 |

35 |

22.75 |

11.5 |

5.875 |

9.5 |

11 |

2-M4×14 |

7 |

|

CFCG-S35×35 |

Ø35 |

35 |

22.45 |

10.9 |

5.875 |

11.5 |

15.2 |

2-M4×14 |

7 |

|

CFCG-S35×45 |

Ø35 |

45 |

27.45 |

10.9 |

6 |

11.5 |

15.2 |

2-M4×14 |

7 |

|

CFCG-S35×50 |

Ø35 |

50 |

29.95 |

10.9 |

6.5 |

11.5 |

15.2 |

2-M4×14 |

7 |

|

CFCG-S40×55 |

Ø40 |

55 |

34.25 |

14.5 |

6.5 |

14 |

18.3 |

2-M5×16 |

10 |

|

CFCG-S40×66 |

Ø40 |

66 |

39.75 |

14.5 |

7.5 |

14 |

18.3 |

2-M5×16 |

10 |

|

型号 |

ØD |

L |

LF |

LP |

F |

Φd3 |

M |

紧固扭矩(N ·M) |

|

CFCG-S45×50 |

Ø45 |

50 |

31.8 |

14.6 |

8.75 |

15 |

2-M5×16 |

10 |

|

CFCG-S45×55 |

Ø45 |

55 |

34.3 |

14.6 |

6.5 |

15 |

2-M5×16 |

10 |

|

CFCG-S45×66 |

Ø45 |

66 |

39.8 |

14.6 |

7.5 |

15 |

2-M5×16 |

10 |

|

CFCG-S55×78 |

Ø55 |

78 |

46.6 |

16.2 |

7.5 |

19 |

4-M6×25 |

15 |

|

CFCG-S65×90 |

Ø65 |

90 |

53.35 |

17.7 |

12 |

22.5 |

4-M8×16 |

30 |

|

CFCG-S80×114 |

Ø80 |

114 |

67.6 |

22.2 |

16 |

28.5 |

4-M8×35 |

30 |

技术参数

|

型号 |

额定扭矩(N ·M) |

最大扭矩(N ·M) |

容许径向(mm) |

容许角向(°) |

容许轴向(mm) |

最高转速(rpm) |

静态扭转刚度(N ·Mrad) |

惯性矩(kg ·M²) |

轴套材质 |

弹性体材质 |

表面处理 |

重量(g) |

|

CFCG-S20×25 |

6 |

12 |

0.1 |

1 |

-0.5+1 |

21700 |

55 |

2.3×10⁻⁶ |

SUS 316 |

德国 |

抛光处理 |

34 |

|

CFCG-S20×30 |

6 |

12 |

0.1 |

1 |

-0.5+1 |

21700 |

55 |

2.5×10⁻⁶ |

43 |

|||

|

CFCG-S25×30 |

12 |

24 |

0.1 |

1 |

-0.5+1 |

18000 |

90 |

1.0×10⁻⁵ |

68 |

|||

|

CFCG-S25×34 |

12 |

24 |

0.1 |

1 |

-0.5+1 |

18000 |

90 |

1.2×10⁻⁵ |

75 |

|||

|

CFCG-S30×35 |

15 |

30 |

0.1 |

1 |

-0.5+1 |

14500 |

130 |

1.4×10⁻⁵ |

114 |

|||

|

CFCG-S35×35 |

18 |

36 |

0.1 |

1 |

-0.5+1 |

12000 |

550 |

1.6×10⁻⁵ |

177 |

|||

|

CFCG-S35×45 |

18 |

36 |

0.1 |

1 |

-0.5+1 |

12000 |

550 |

1.7×10⁻⁵ |

225 |

|||

|

CFCG-S35×50 |

18 |

36 |

0.1 |

1 |

-0.5+1 |

12000 |

550 |

1.8×10⁻⁵ |

240 |

|||

|

CFCG-S40×55 |

20 |

40 |

0.1 |

1 |

-0.5+1 |

10000 |

1200 |

8.7×10⁻⁵ |

289 |

|||

|

CFCG-S40×66 |

20 |

40 |

0.1 |

1 |

-0.5+1 |

10000 |

1200 |

8.9×10⁻⁵ |

351 |

|||

|

CFCG-S45×50 |

30 |

60 |

0.1 |

1 |

-0.5+1 |

7700 |

1800 |

9.2×10⁻⁵ |

524 |

|||

|

CFCG-S45×55 |

30 |

60 |

0.1 |

1 |

-0.5+1 |

7700 |

1800 |

9.5×10⁻⁵ |

457 |

|||

|

CFCG-S45×66 |

30 |

60 |

0.1 |

1 |

-0.5+1 |

7700 |

1800 |

9.8×10⁻⁵ |

525 |

|||

|

CFCG-S55×78 |

60 |

120 |

0.1 |

1 |

-0.5+1 |

7000 |

2500 |

3.6×10⁻³ |

778 |

|||

|

CFCG-S65×90 |

140 |

280 |

0.1 |

1 |

-0.5+1 |

6300 |

3800 |

8.7×10⁻³ |

1329 |

|||

|

CFCG-S80×114 |

185 |

370 |

0.1 |

1 |

-0.5+1 |

5600 |

4000 |

4.1×10⁻² |

2280 |

标准轴径

|

型号 |

标准轴径(Ød1、Ød2)mm |

||||||||||||||||||

|

4 |

5 |

6 |

6.35 |

7 |

8 |

9.52 |

10 |

11 |

12 |

12.7 |

14 |

15 |

16 |

18 |

19 |

20 |

22 |

24 |

|

|

CFCG-S20×25 |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||||

|

CFCG-S20×30 |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||||

|

CFCG-S25×30 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||

|

CFCG-S25×34 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||

|

CFCG-S30×35 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||

|

CFCG-S35×35 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||

|

CFCG-S35×45 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||

|

CFCG-S35×50 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||

|

CFCG-S40×55 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||

|

CFCG-S40×66 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||

|

型号 |

标准轴径(Ød1、Ød2)mm |

||||||||||||||||||||||

|

8 |

9.52 |

10 |

11 |

12 |

12.7 |

14 |

15 |

16 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

42 |

45 |

|

|

CFCG-S45×50 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||

|

CFCG-S45×55 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||

|

CFCG-S45×66 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||||

|

CFCG-S55×78 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||||||

|

CFCG-S65×90 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||||

|

CFCG-S80×114 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||||||

注:为了增强轴套夹持力,标配螺丝为12.9级高强度螺丝,12.9级高强度螺丝扭力约大于不锈钢螺丝30%左右,如需不锈钢螺丝,需特别注明。

D14-D30 (4-瓣胶体)

D35-D45 (6-瓣胶体)

D55-D105 (8-瓣胶体)

注:为了增强轴套夹持力,标配螺丝为12.9级高强度螺丝,12.9级高强度螺丝扭力约大于不锈钢螺丝30%左右,如需不锈钢螺丝,需特别注明。