特点:

高精度、专为伺服、步进电机设计

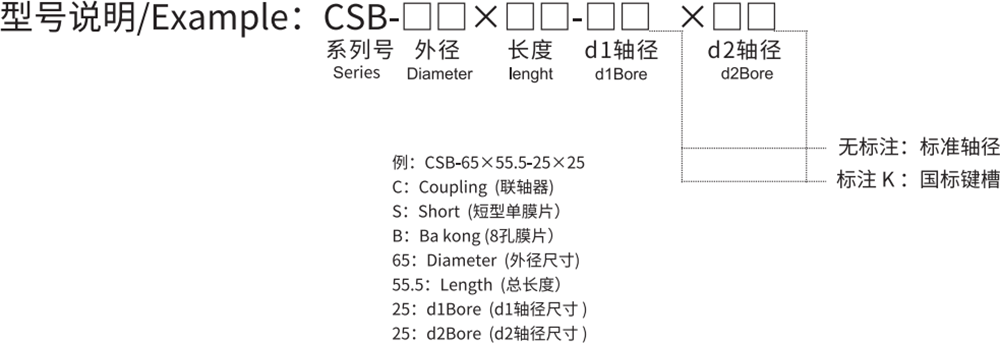

采用8孔膜片,高刚性、大扭矩、螺丝不易松脱

无间隙的轴和轴套连接,适用于正反转

膜片采用不锈钢制成,抗疲劳性特好

夹紧紧固方式

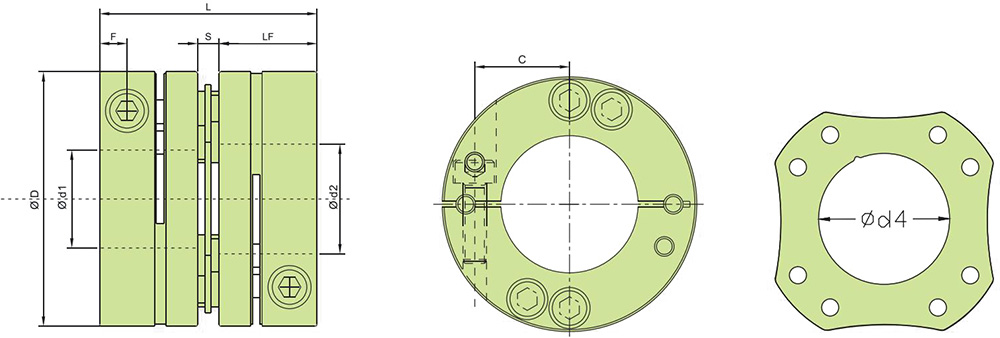

外型尺寸 (单位): mm

|

型号 |

ØD |

L |

LF |

Ød4 |

S |

F |

C |

M |

|

|

CSB-56×45 |

Ø56 |

45.3 |

19.75 |

Ø26 |

5.8 |

6.4 |

19.5 |

2-M5×25 |

10 |

|

CSB-65×55.5 |

Ø65 |

55.4 |

24.5 |

Ø36 |

6.4 |

7.5 |

22.5 |

2-M6×30 |

15 |

|

CSB-68×54 |

Ø68 |

54.1 |

23.35 |

Ø36 |

7.4 |

7.7 |

23.5 |

2-M6×35 |

15 |

|

CSB-87×68 |

Ø87 |

67.9 |

30 |

Ø46 |

7.9 |

9.4 |

30 |

2-M8×35 |

30 |

技术参数

|

型号 |

额定扭矩(N ·M) |

最大扭矩(N ·M) |

容许径向(mm) |

容许角向(°) |

容许轴向(mm) |

最高转速(rpm) |

Static torsional siffness(N ·Mrad) |

Moment of inertia(kg ·M²) |

轴套材质 |

弹性体材质 |

表面处理 |

重量(g) |

|

CSB-56×45 |

32.5 |

65 |

0.15 |

0.6° |

±0.3 |

12000 |

96000 |

1.4×10⁻⁴ |

AL6061-T6 |

SUS 304 |

阳极氧化处理 |

770 |

|

CSB-65×55.5 |

62 |

124 |

0.15 |

0.6° |

±0.3 |

10000 |

120000 |

2.1×10⁻⁴ |

1275 |

|||

|

CSB-68×54 |

72 |

714 |

0.15 |

0.6° |

±0.3 |

10000 |

140000 |

0.27×10⁻³ |

1343 |

|||

|

CSB-87×68 |

120 |

240 |

0.15 |

0.6° |

±0.3 |

8000 |

330000 |

0.85×10⁻³ |

2824 |

注:以上技术参数由最大孔径规格测得

标准轴径

|

型号 |

标准轴径( ØD1 、ØD2 )mm |

||||||||||||||||||||

|

12 |

12.7 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

22 |

24 |

25 |

28 |

30 |

32 |

35 |

38 |

40 |

45 |

48 |

50 |

|

|

CSB-56×45 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||||

|

CSB-65×55.5 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||

|

CSB-68×54 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

||||||||

|

CSB-87×68 |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

● |

|||||||